Resolving boundary layers with a high-quality computational mesh is paramount in computational fluid dynamics (CFD) because these regions, characterized by sharp gradients in velocity, temperature, and other flow properties, dictate crucial phenomena like drag, heat transfer, and flow separation. An inadequate mesh in the boundary layer, typically too coarse or poorly structured, will inaccurately capture these steep gradients, leading to significant errors in the numerical solution. This can manifest as an over- or under-prediction of drag, an incorrect representation of heat transfer rates, or a failure to predict flow separation accurately, all of which can render the simulation results unreliable for engineering design and analysis.

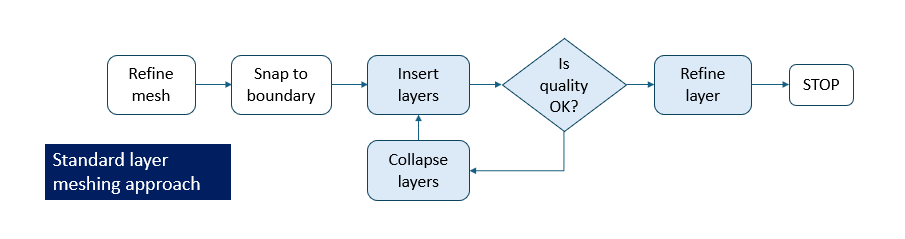

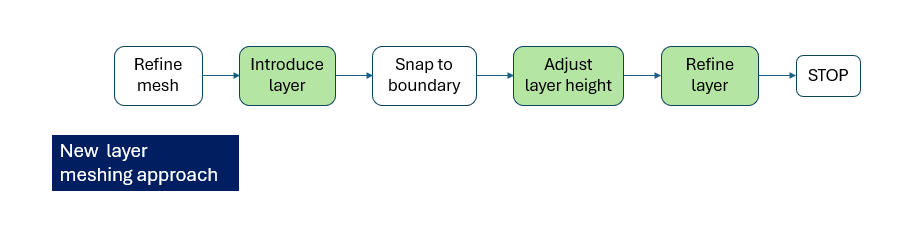

In typical layer meshing approaches such as that employed in many OpenFOAM variants, isolated collapses are occasionally encountered in the layer mesh. These local layer collapses occur due to mesh quality constraints, and result in an iterative layer mesh generation process as illustrated in the flow diagram below:

Local layer collapses are associated with jumps in y+ values which can have a noticeable influence on the solution. Despite tuning of the meshing parameters to try to improve layer coverage and avoid layer collapses, occasionally they will still happen. Local layer collapses prevent the accurate modelling of the boundary layer in the flow solution and compromise the solution accuracy. They can also make it difficult to distinguish changes in results due to part modifications (i.e. geometry sensitivity) from changes due to local layer collapses (mesh sensitivity).

Local layer collapses are associated with jumps in y+ values which can have a noticeable influence on the solution. Despite tuning of the meshing parameters to try to improve layer coverage and avoid layer collapses, occasionally they will still happen. Local layer collapses prevent the accurate modelling of the boundary layer in the flow solution and compromise the solution accuracy. They can also make it difficult to distinguish changes in results due to part modifications (i.e. geometry sensitivity) from changes due to local layer collapses (mesh sensitivity).

To avoid the problems associated with layer collapses, a new layer meshing approach was developed in iconCFD V5. In the new full-layer meshing approach, a single layer is introduced into the mesh prior to snapping. The topology of this layer is preserved throughout the snapping process.

The outer surface of this single layer is then adjusted to meet the target layer height and the layer is refined based on the specified layer parameters. This process avoids the iteration during the layer generation process and facilitates the generation of meshes suitable for low Re number modelling.

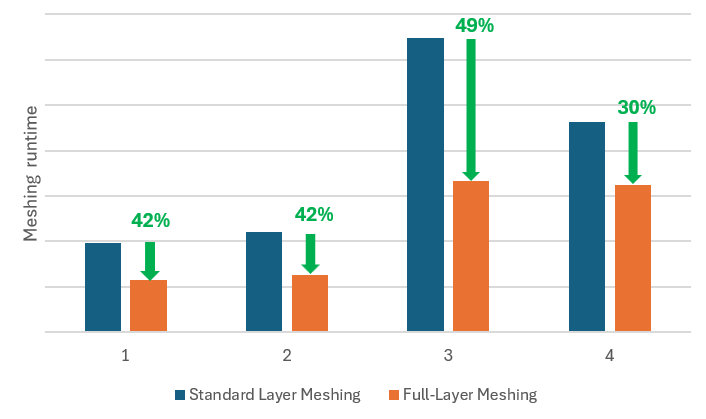

The new full-layer meshing capability in iconCFD V5 is a robust approach which has been tested successfully on a wide range of industrial configurations, both internally and by our OEM customers. As well as allowing simple generation of low Re meshes, the new approach also improves the speed of meshing by eliminating iteration within the layer meshing process. This is illustrated in the meshing times given in the graph below for a selection of industrial automotive cases.

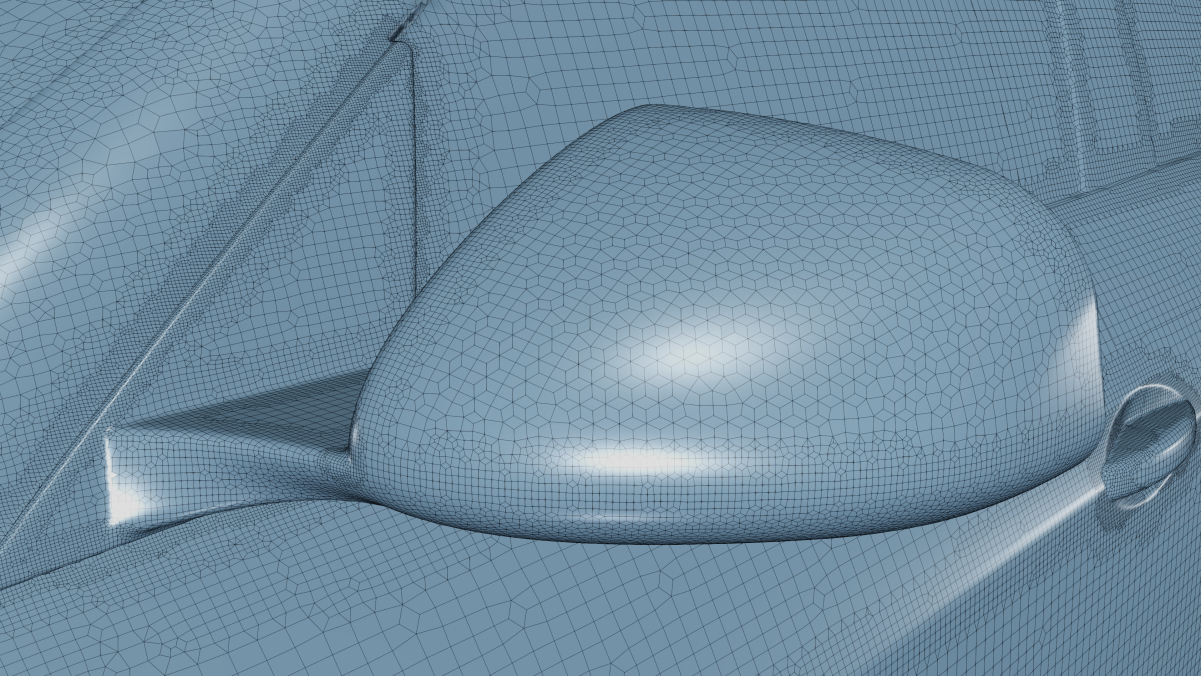

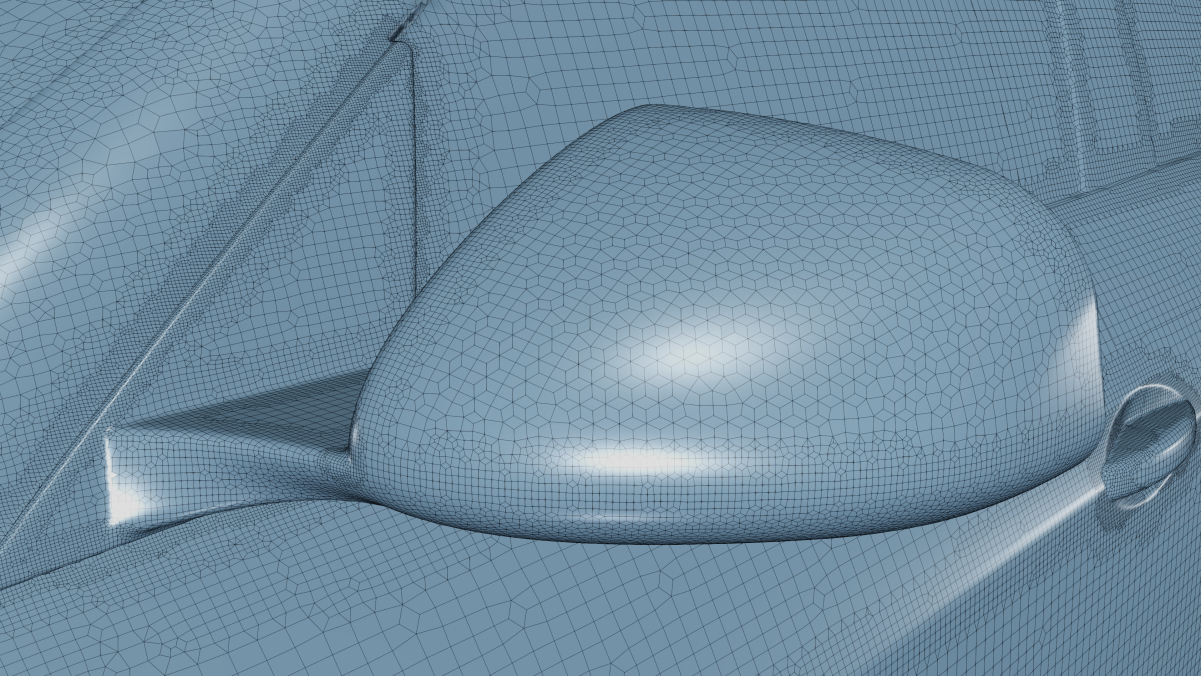

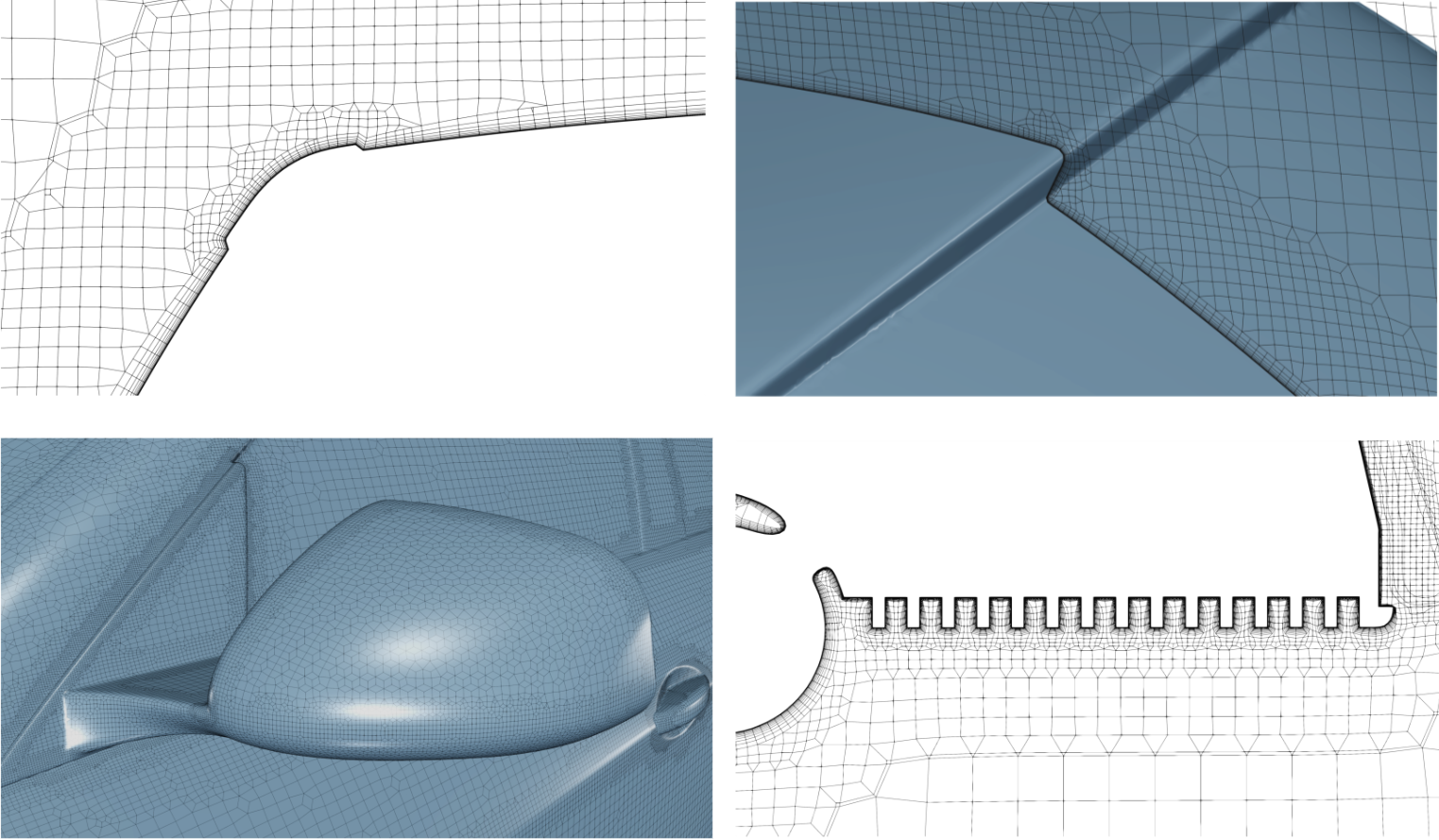

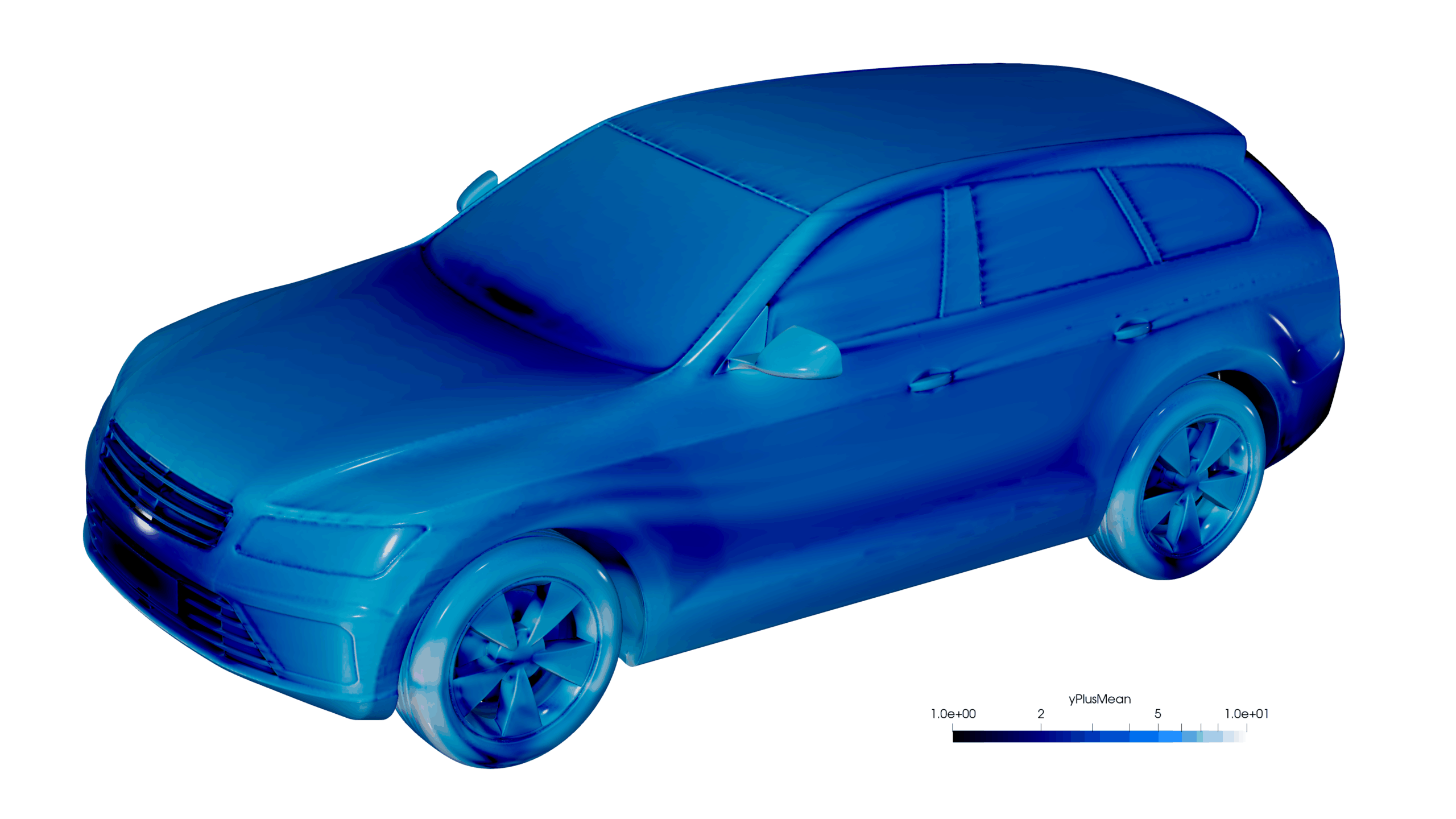

Crucially, full-layer meshing reduces mesh sensitivity of the flow simulation by completely avoiding layer collapses and ensuring proper resolution of viscous boundary layers. The following images demonstrate the high quality low Re mesh obtained on the AeroSUV model with 20 layers specified across the vehicle body and 4 layers on the wheels.

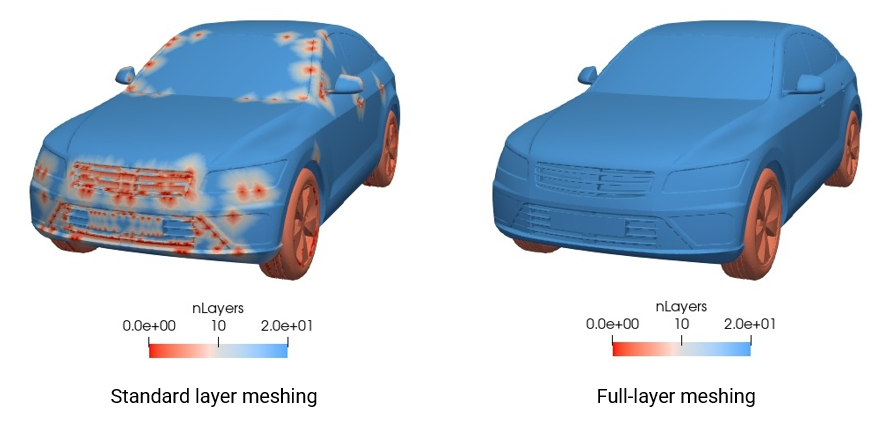

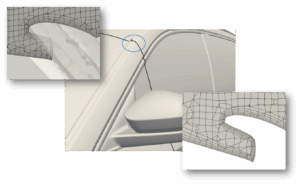

The impact of the full-layer meshing approach can be clearly seen below in the images of low Re meshes obtained on the AeroSUV model with standard layer meshing approach compared to full-layer meshing.

Numerous local layer collapses are evident with the standard iterative layer meshing, particularly around complex geometric features of the model. The effect of these local layer collapses also propagates quite a long way through the layer mesh. In contrast, full-layer meshing can achieve the full 20 layers across the entire vehicle surface.

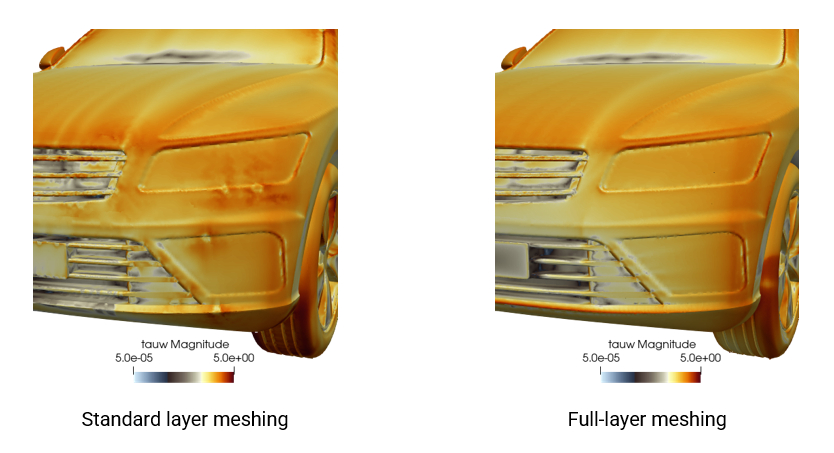

In standard layer meshing, local layer collapses result in a discontinuous wall shear stress (tauw) on the surface of the vehicle. These unphysical peaks are undesirable, particularly at the front of the vehicle, as they will influence the development of the downstream flow. Using full-layer meshing, there are no layer collapses, and the wall shear stress field is much smoother.

With iconCFD V5 users no longer need worry about how well the boundary layer flow is captured by the mesh and can resolve down to the wall perfectly on the most complex of geometries.

“The new full layer meshing capability in iconCFD provides collapse-free and low y+ prismatic layers on complex industrial geometries. This has unlocked a new level of accuracy in water management CFD simulations.” – Martin Černý, project manager of aeroacoustics and soiling simulations ŠKODA AUTO.

Slices through a mesh generated for soiling simulation using full layer meshing

(images courtesy of ŠKODA AUTO)

The full-layer meshing in iconCFD V5 provides the means for accurate capture of boundary layer physics, leading to robust and trustworthy CFD predictions.