Windsor, Bedford, UK, 27 September 2012

ICON and ARA, two of the UK’s leading innovators in the development and support of Computational Fluids Dynamics (CFD) processes, are pleased to announce that they have signed a strategic partnership. Their joint expertise in CFD technology development, along with ARA’s ability to combine wind tunnel testing and the complementary services of model design, component manufacture and aerodynamic analysis, means the partnership can offer high quality, fully validated products to the aerospace industry.

ICON, who since 1992 has supplied high value-added, supported CFD-driven design technologies to a variety of industries worldwide, including AIRBUS and its component suppliers, is excited to be working on collaborative software technologies with ARA, who will be able to validate the civil and defence applications using their established test facilities and extensive experience in aeronautical applications.

Bob Bosher, Chief Operations Officer at ARA said “We are delighted to be working with ICON on mutual technology collaborations and service offerings which will be provided globally to civil and defence aircraft manufacturers”.

David Green, Commercial Director at ICON, stated that: “ARA was a natural choice as a partner with its extensive experience in working with global aerospace manufacturers in a number of different technology areas, combined with a company culture that fits well with ICON – focussed upon providing excellent customer service. We are looking forward to this collaboration”.

![]() About ARA (www.ara.co.uk)

About ARA (www.ara.co.uk)

Aircraft Research Association was established in 1952 as a wind tunnel test centre for the UK aircraft industry by 14 British aerospace companies. Today, this independent non-profit distributing research and development company has gained worldwide recognition as a centre of excellence, providing the aerospace industry with high quality aerodynamic and related services and facilities to support the design, development and through-life upgrades of commercial aircraft, military aircraft and defence system programmes. For more information visit www.ara.co.uk or contact Nigel Corby on 01234 350681, business@ara.co.uk

![]() About Icon Technology & Process Consulting Limited (www.iconcfd.com)

About Icon Technology & Process Consulting Limited (www.iconcfd.com)

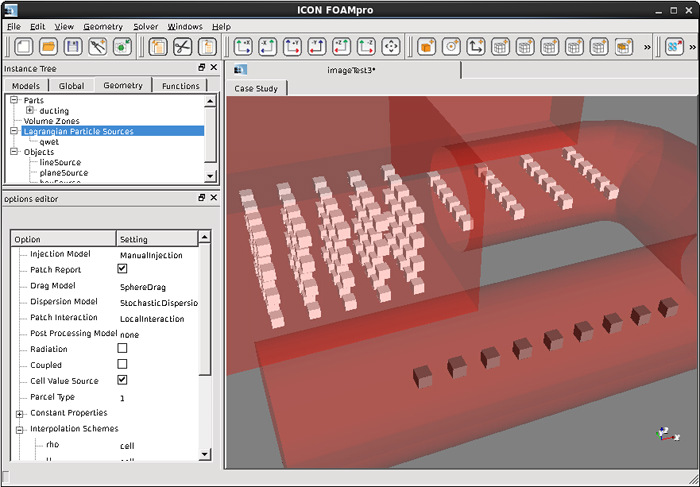

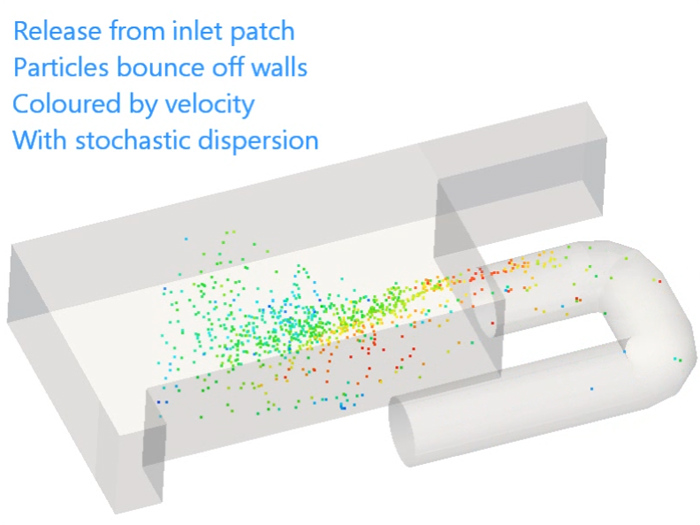

ICON is a privately-owned CFD technology company formed in 1992. ICON’s strategy is as pertinent today as it was then: to provide high-quality independent advice and expertise in process, technology and services.

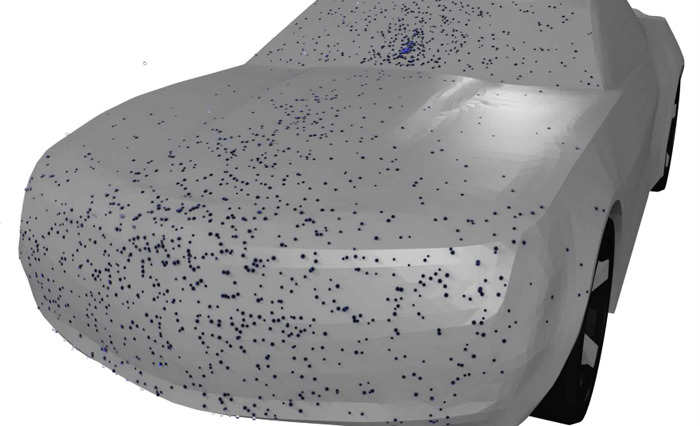

ICON has extensive experience in the use of proprietary software for CFD simulation and optimization, together with expertise in developing and supporting open source CFD technologies. ICON supports customers from a variety of industries including aerospace, automotive, consumer goods, energy and processing sectors.

The company head-quarters are in Windsor, UK with further offices throughout Europe and the USA (Cincinnati, OH).

For further information please visit iconcfd.com/contact.